Over 2015-2020, I decided to build open source tools that were successively more complex. The goal was to use each tool to build the next....

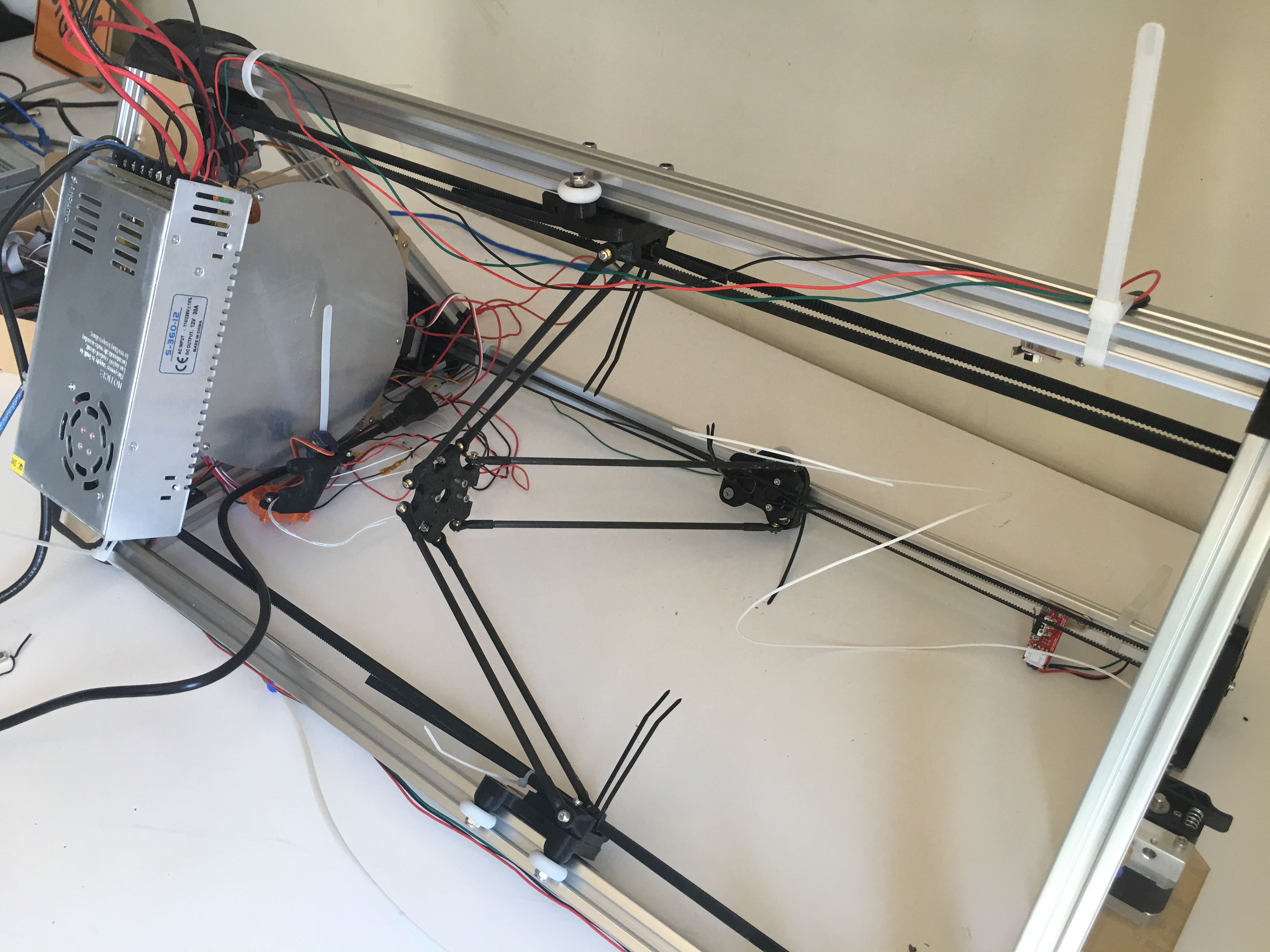

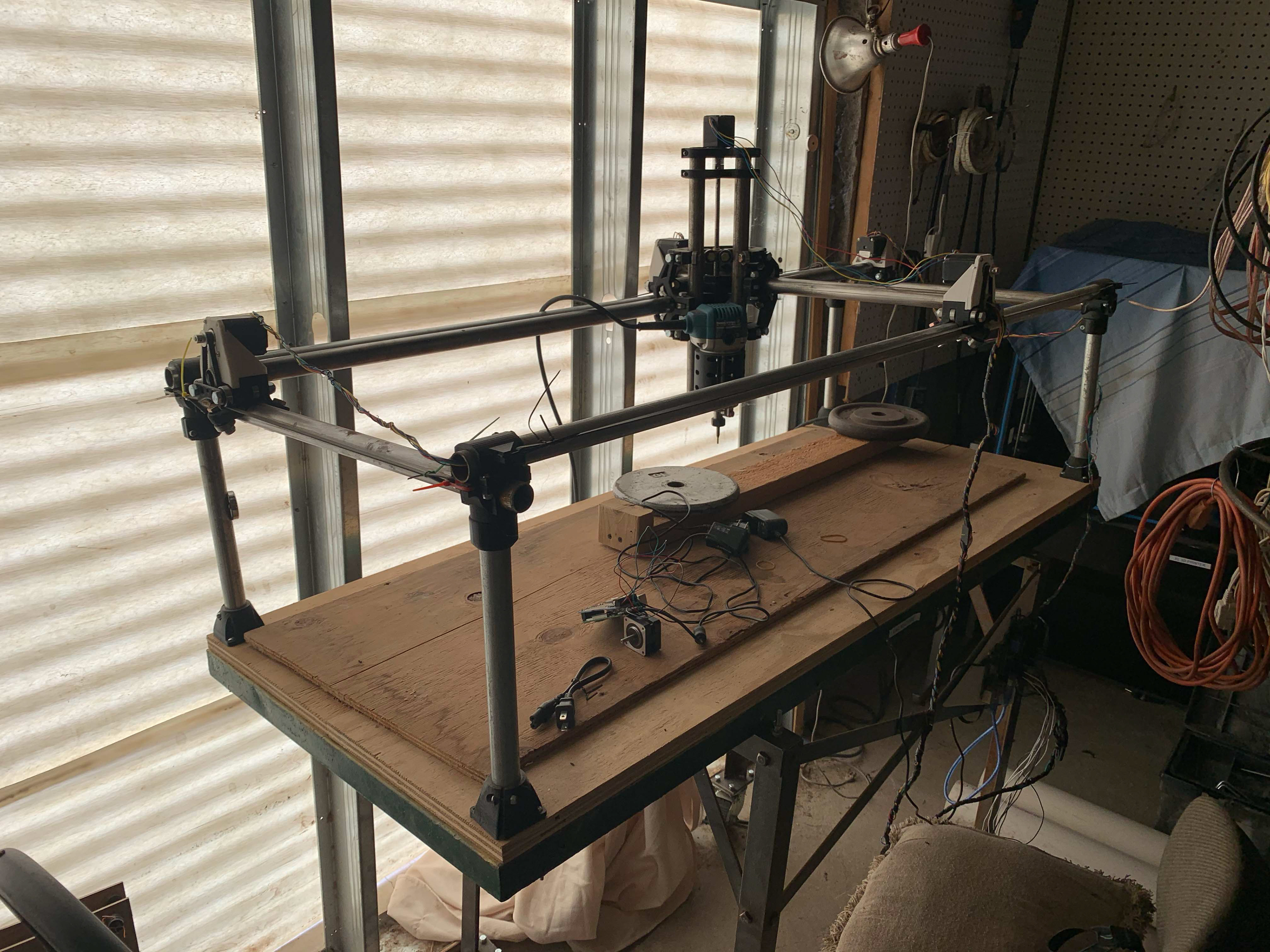

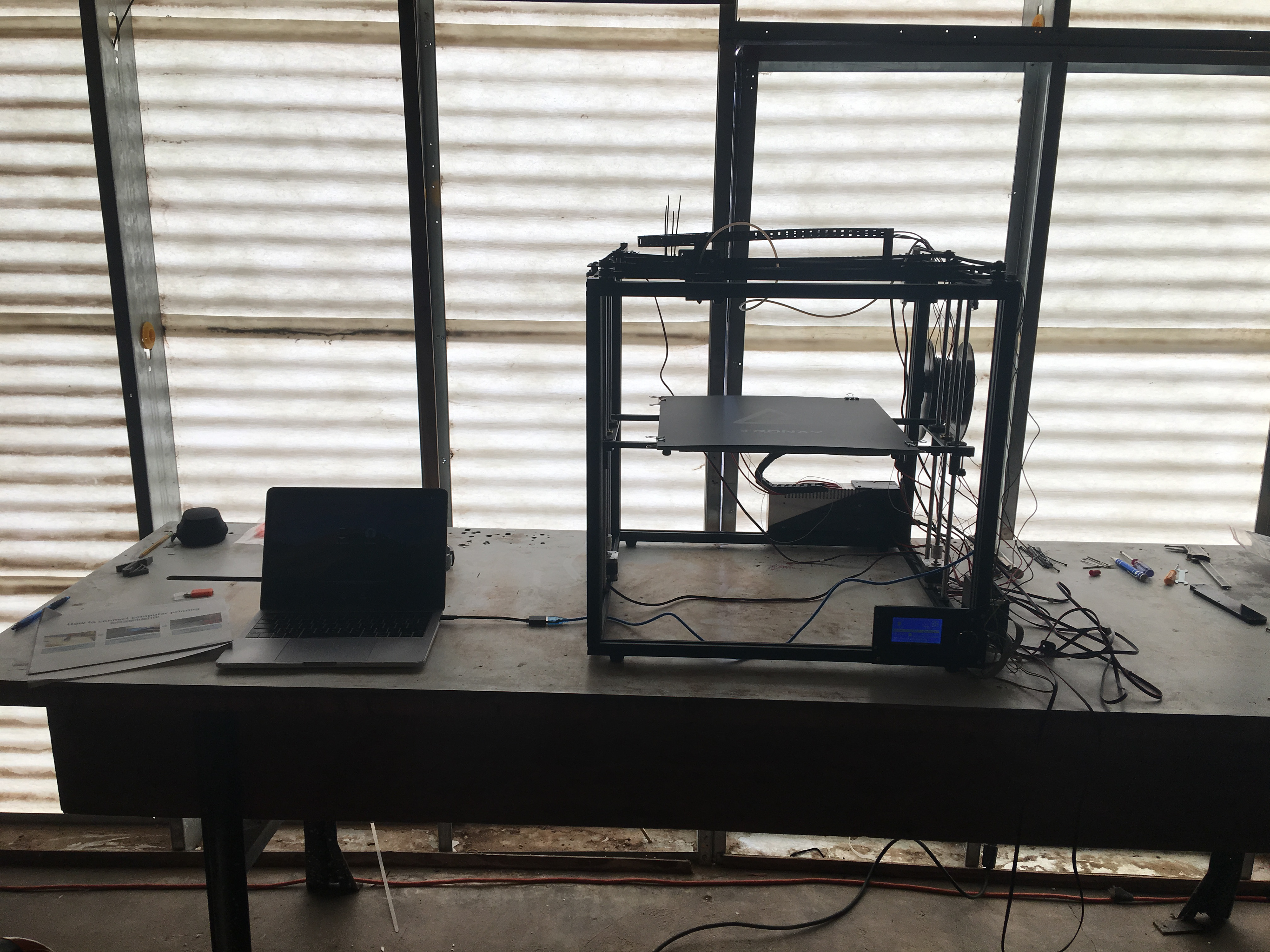

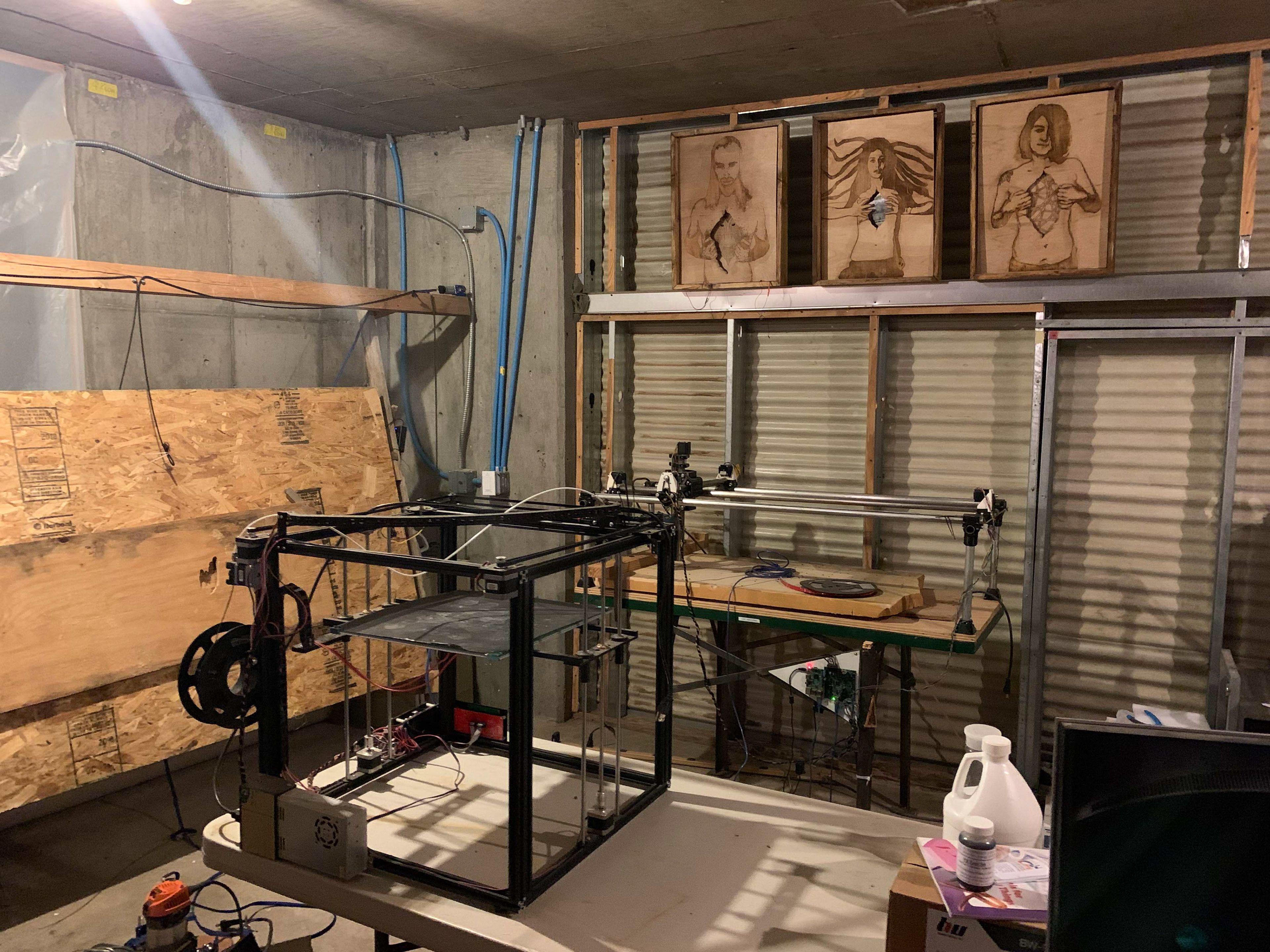

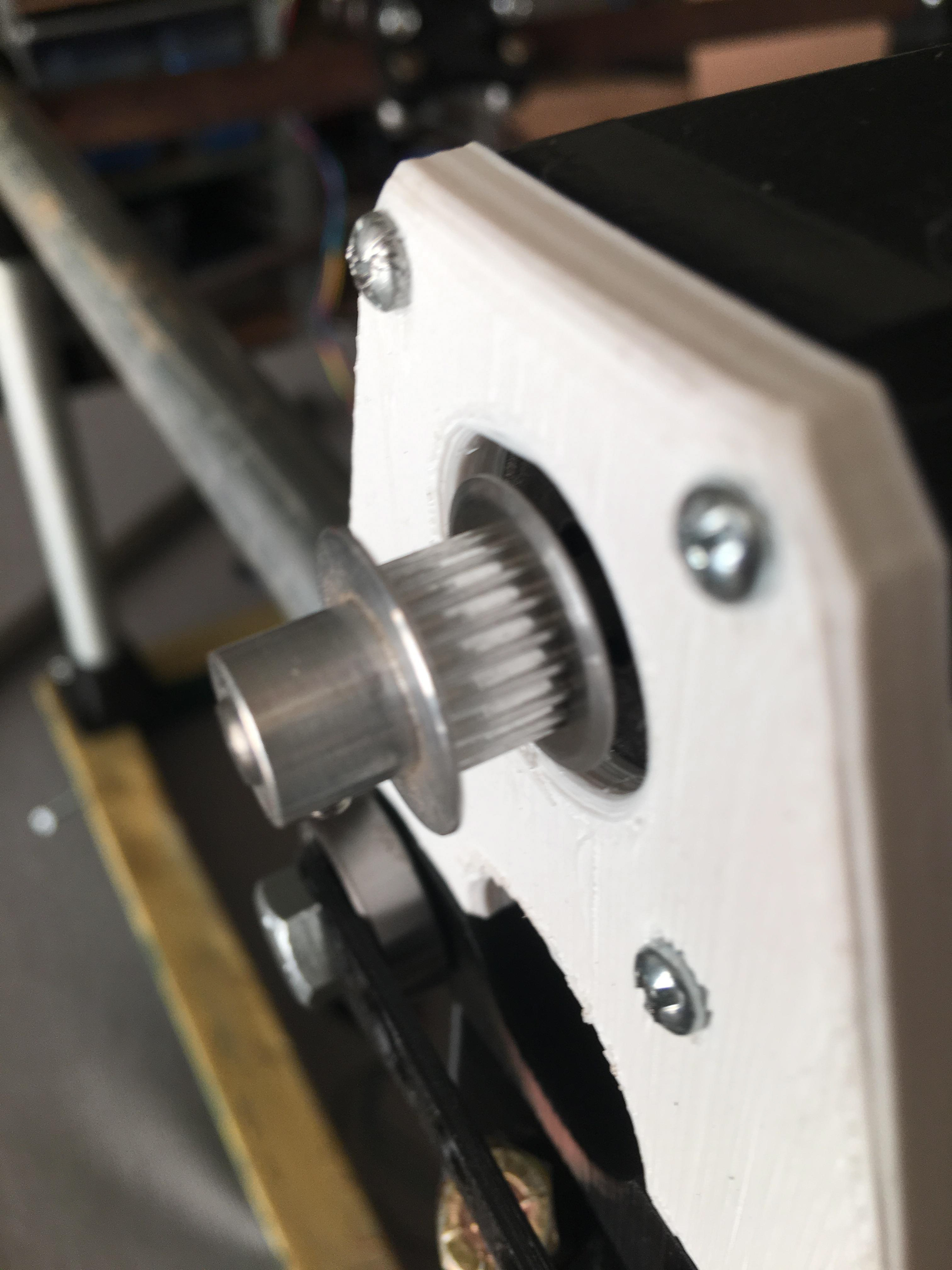

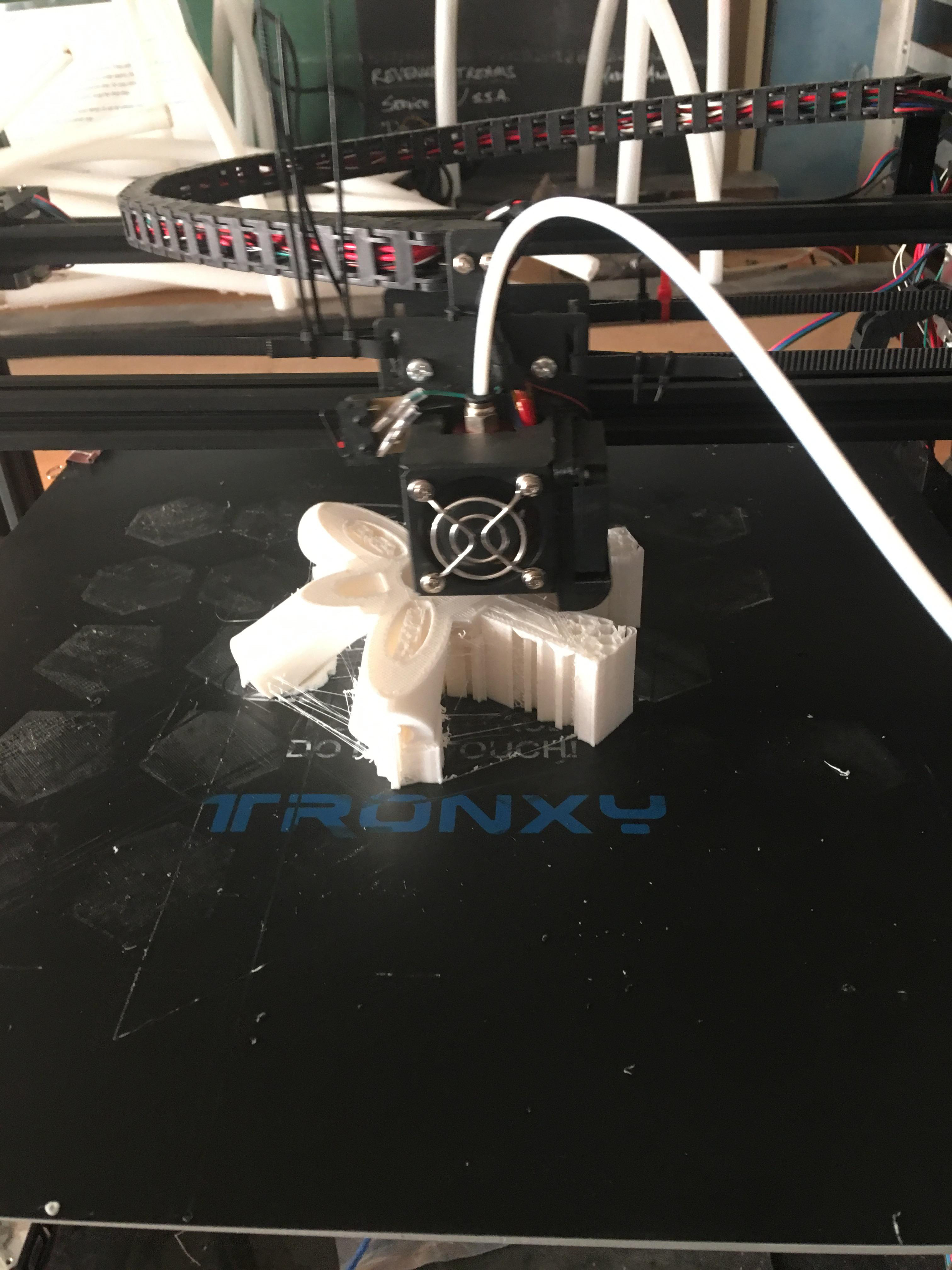

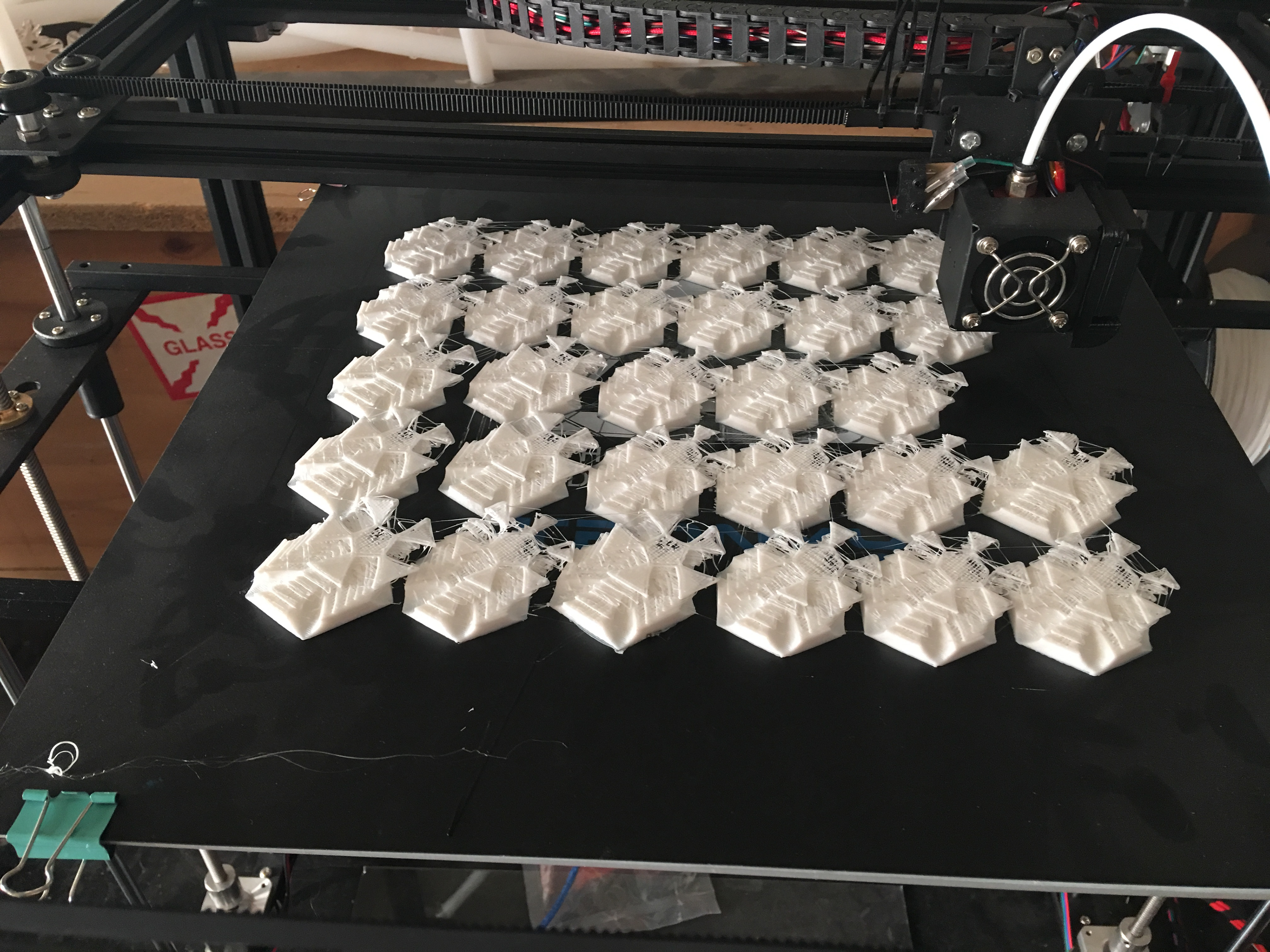

Following this methodology, I started with a basic 3d printer (Printer 1) from parts I had been given. It was a generic RepRap. I then printed parts for a more complex 3d printer (Printer 2) , which in turn made parts for a small CNC machine (CNC 1), the MPCNC. I used this to make a larger 4x8' Maslow CNC (CNC 2) sled. Finally, I used Printer 2 and CNC 2 to make a Lowrider CNC (CNC 3).

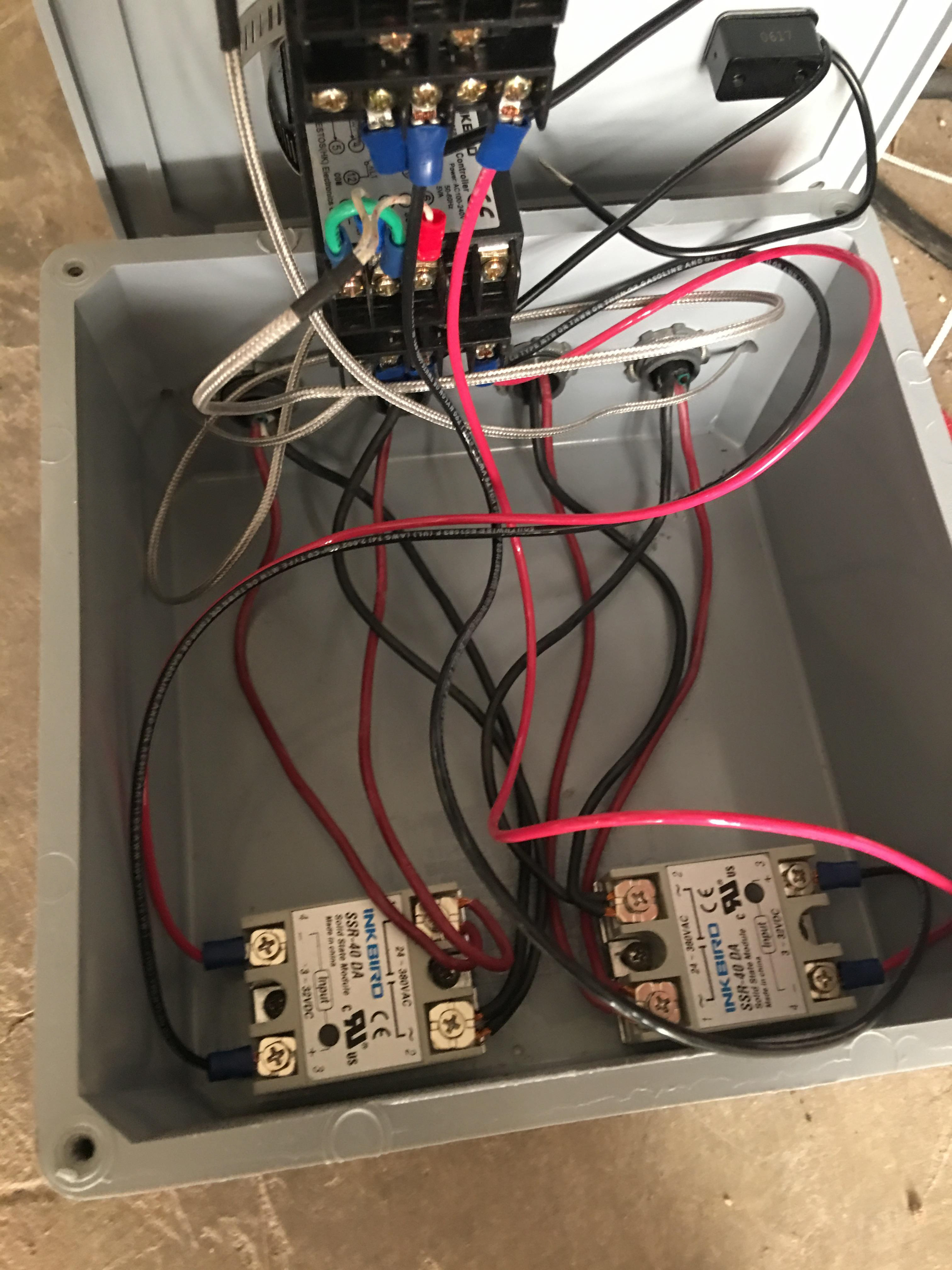

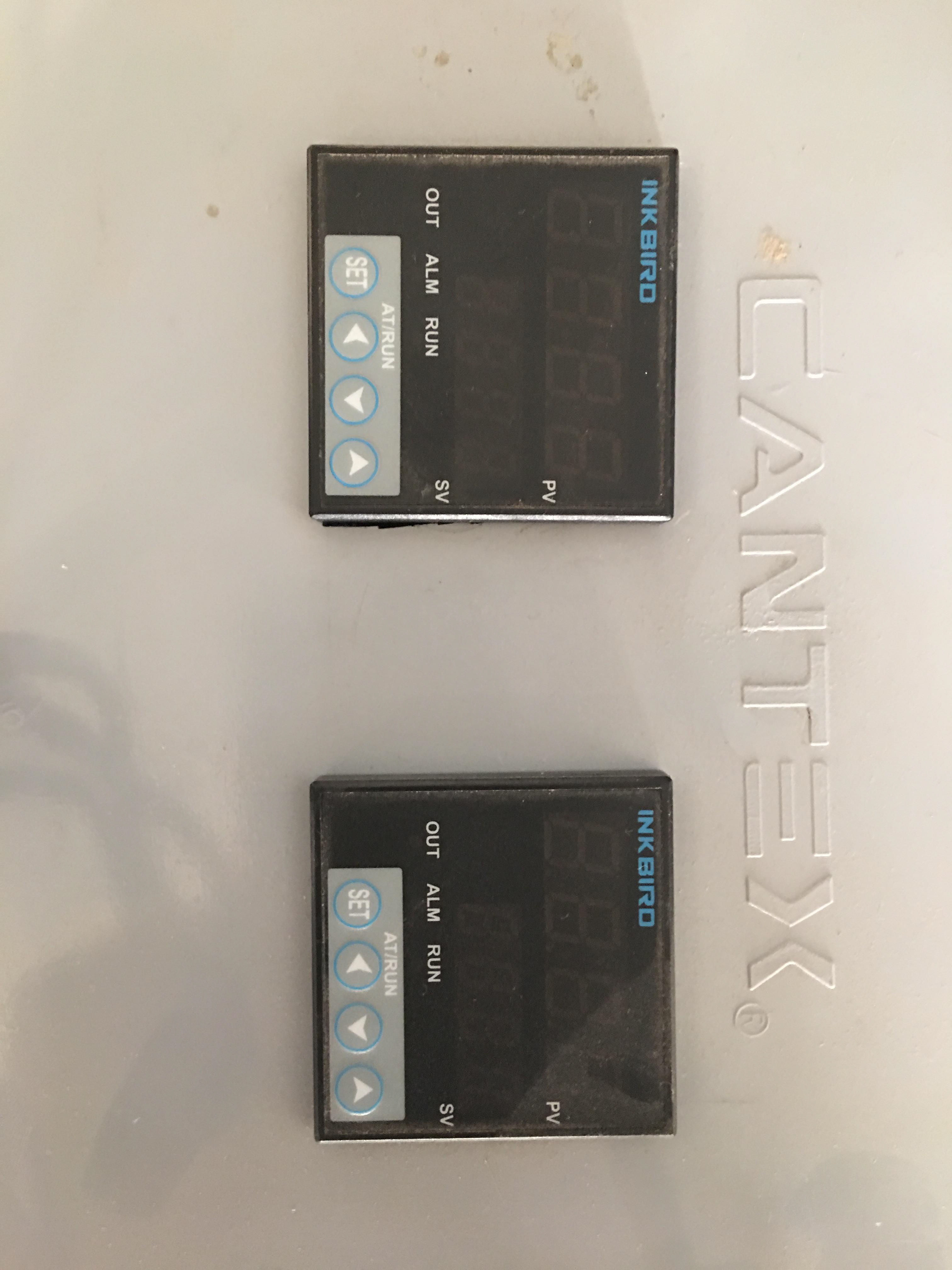

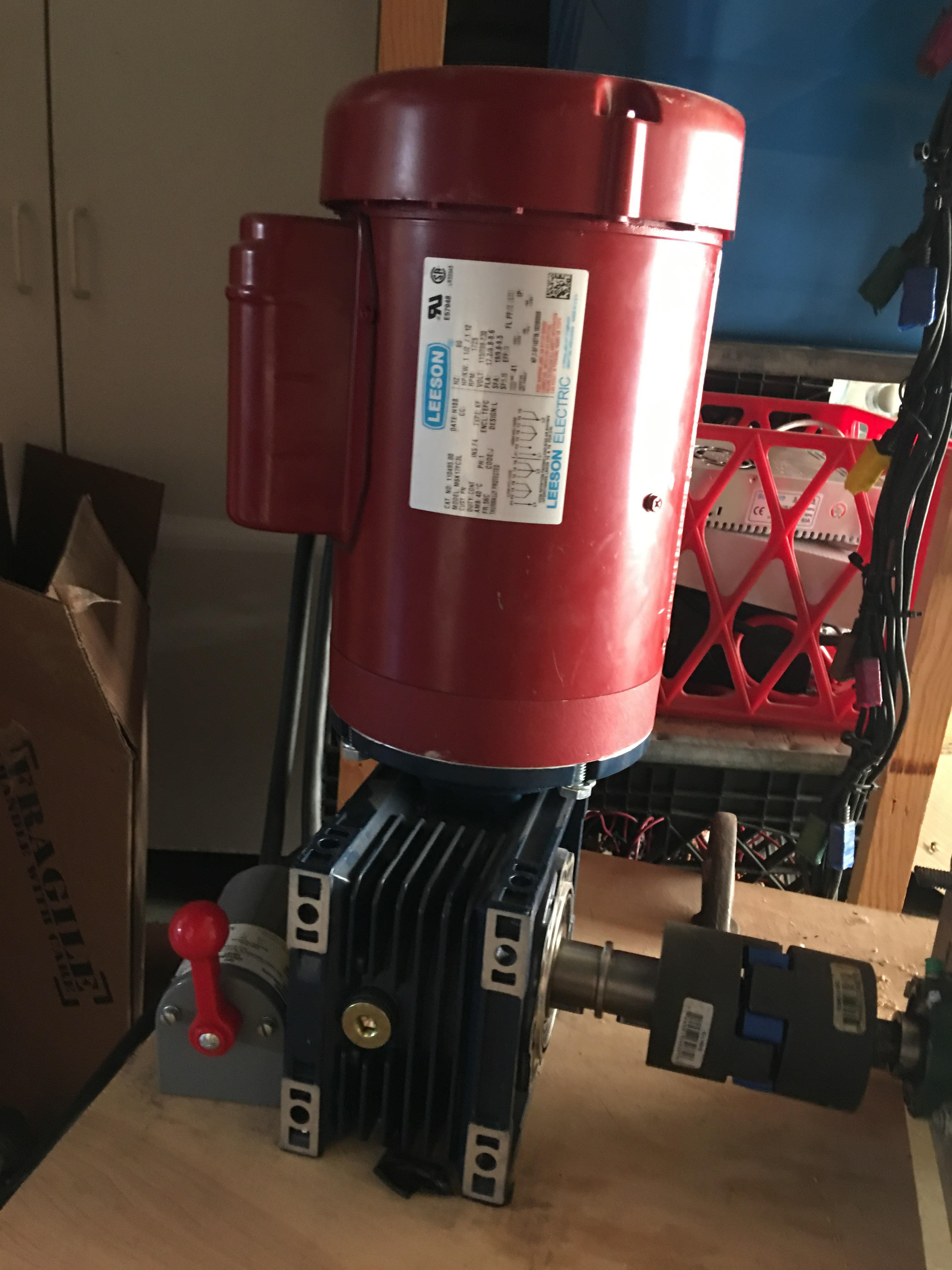

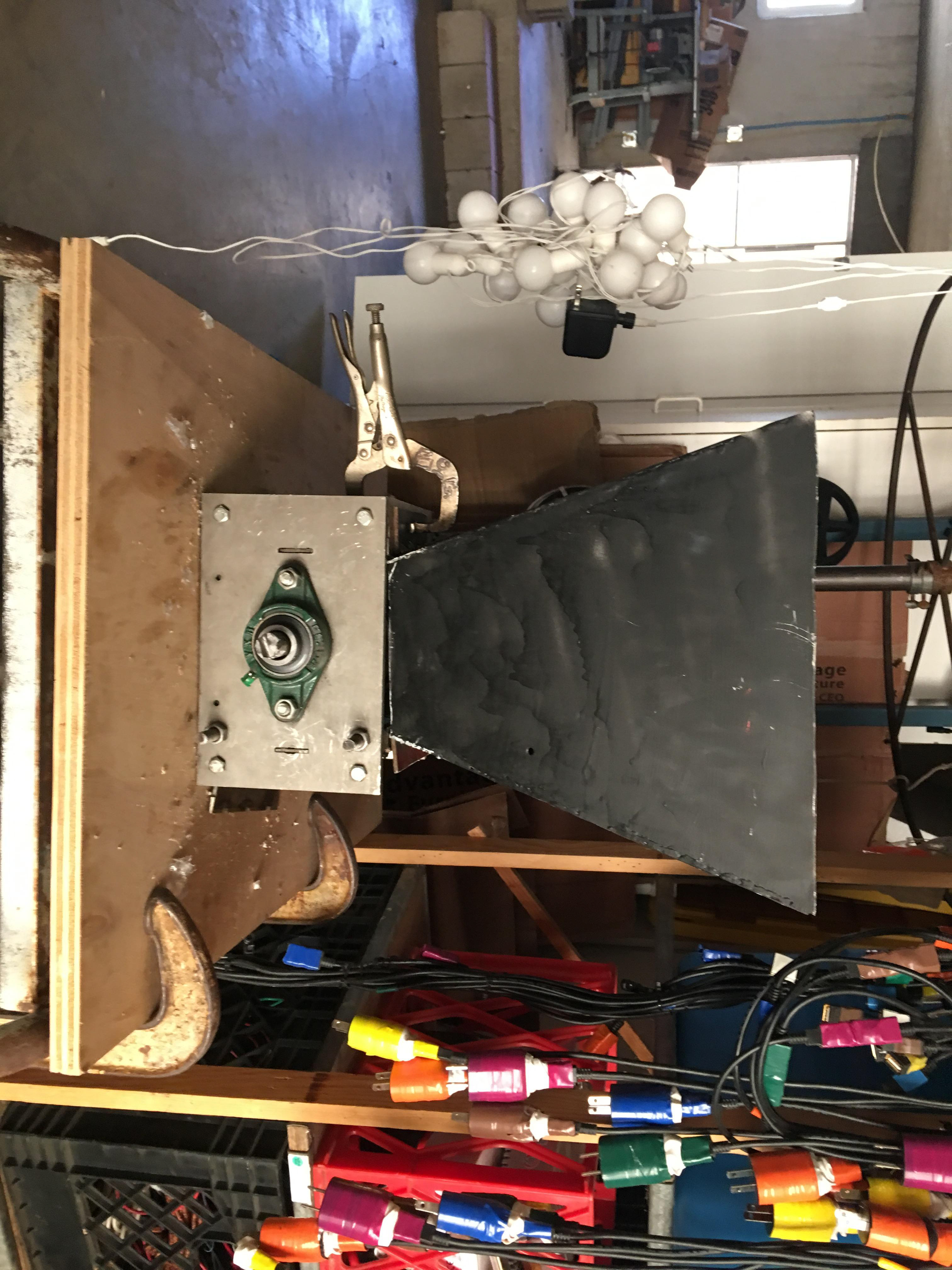

Next, I wanted to reclaim materials to fabricate parts. I made a plastic shredder and injection molder from Precious Plastic. This allows me to make aluminum molds with the CNC, that I could then use to inject into parts using reclaimed plastic from the shredder.

I started working with a friend to design the aluminum molds but ended up moving away and leaving most of these machines behind before finishing. All in all, I built 7 tools, and learned a lot on DIY mechanical engineering with found materials and open source plans.